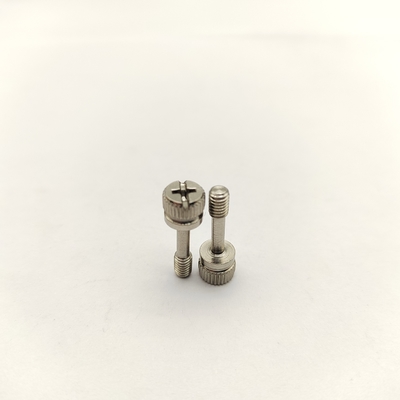

A4 Knurled Captive Screws 316 SS Combo Phillips/Slotted Medical & Lab Equipment Easy Clean

Productdetails:

| Plaats van herkomst: | China |

| Merknaam: | guanbiao |

| Certificering: | ISO9001 |

| Modelnummer: | M5*20 |

Betalen & Verzenden Algemene voorwaarden:

| Min. bestelaantal: | 50000 |

|---|---|

| Prijs: | negotiable |

| Verpakking Details: | Plastic zak + karton + pallet |

| Levertijd: | 15-20 werkdagen |

| Betalingscondities: | t/t |

| Levering vermogen: | 5000000 |

|

Gedetailleerde informatie |

|||

| Vormtype: | Ronde kop | Grootte: | Verscheidene afmetingen beschikbaar |

|---|---|---|---|

| Productieproces: | Koude rubriek, koud smeedstuk | Draad: | M2, M2.6, M3, M3.5, M4, M5 |

| Materiaal van het product: | Roestvrij staal | roestbewijs: | - Ja, dat klopt. |

| OEM: | Ja, welkom, volgens uw tekening. | Trade Term: | EXW |

| Shape: | Flat Head | Schroeflengte: | 10 - 150mm |

| Totale lengte: | 40.0 mm | Case Hardness: | HV210-270 |

| Kleur: | Zilverwit / Natuur | ||

Productomschrijving

Knurled Captive Screws A2 Combo Phillips/Slotted Server Rack & Enclosure

Premium A4-70 knurled captive screws for corrosive/clean environments. Combo drive, captive design. Passivated or electropolished. For medical devices, lab & food processing equipment. Hygienic.

Meet the demanding hygiene and corrosion resistance requirements of medical, laboratory, and food processing equipment with our **A4 Stainless Steel Knurled Captive Screws**. Crafted from A4-70 (316) stainless steel, they offer **superior resistance** to salt water, chemicals, acids, and frequent cleaning agents. The **partially knurled cylindrical head** enables easy, frequent access, while the **smooth lower section** minimizes crevices for easy cleaning. The **Phillips/Slotted combo drive** ensures secure installation. The **captive washer system** prevents screw loss, critical in sterile environments. Available passivated or electropolished for maximum smoothness and cleanability.

![]()

TECHNICAL SPECIFICATIONS |

|

| Material | A4-70 Stainless Steel (316)** (ISO 3506) |

| Drive Type | Phillips/Slotted Combination (PH2 Phillips + 3-4mm Slotted) |

| Head Style | Cylindrical Head (Smooth lower shank, **Knurled upper grip section** - Fine groove knurl) |

| Sizes (Diameter x Length): | Common: * M4 x 8mm, 10mm, 12mm, 16mm (Knurl Dia: ~6-7mm) * M5 x 10mm, 12mm, 16mm, 20mm (Knurl Dia: ~7-8mm) * M6 x 12mm, 16mm, 20mm, 25mm (Knurl Dia: ~9-10mm) |

| Surface Finish | Passivated (Standard)** or **Electropolished (EP)** (Recommended for high hygiene) |

| Panel Thickness Range | 1.0mm - 3.0mm. |

![]()

Primary Uses & Applications:

* Medical device housings & access panels.

* Laboratory equipment & analyzers.

* Pharmaceutical processing & packaging machinery.

* Food & beverage processing equipment.

* Biotech & cleanroom instrumentation.

* Marine scientific equipment.

* Chemical handling systems.

* Any application requiring frequent access, high corrosion resistance, and easy cleaning/sanitization.

Surface Treatment/Finishes:

* **Passivation (Standard):** Mandatory for corrosion resistance. Removes free iron.

* **Electropolishing (Highly Recommended):** Significantly smoothes surfaces (Ra < 0.4 µm), removes micro-imperfections, enhances corrosion resistance, improves cleanability, reduces bacterial adhesion, and provides a bright, easy-to-inspect finish. Compliant with FDA, USDA, 3-A Sanitary Standards for hygienic applications.

![]()

How to Use:

1. **Panel Prep:** Install **A4 stainless steel captive receptacles** (threaded inserts/standoffs) into the frame. Ensure material compatibility.

2. **Insert Assembly:** Insert the captive screw assembly through the panel hole.

3. **Installation (Tool):** Use a **clean PH2 or slotted driver** to tighten the screw securely. Achieve metal-to-metal contact for grounding if needed. *Follow sanitized handling procedures.*

4. **Tool-Less Access:** For routine access, **hand-tighten/loosen using the knurled grip**. The captive design prevents screws from falling into sensitive areas.

5. **Cleaning:** The smooth surfaces (especially electropolished) and minimized crevices allow for effective cleaning, wiping, spraying, or autoclaving (check EP specs). No threads are exposed when tightened.

6. **Inspection:** The bright EP finish allows easy visual inspection for damage or contamination.